We use no-dysprosium formula on round-low-grade products for customers to reduce costs. We have a stable formula which can be made into low temperature coefficient products. It reduces costs and increases efficiency further for customers with strictly control the tolerance in processing and the coating according to different requirements of customers to ensure the stability of plating protection at the same time, including salt spray, coating binding force, colloid affinity and so on.

Round products are prone to missing corners in the production process. So we have automatic full inspection equipment for appearance tolerances, which can ensure product defects within the controllable range and avoid defective products in using process.

In terms of flux consistency, we ensure fixed-point sintering furnace to the consistency of magnet process control, and magnetic flux full inspection equipment to prevent weak magnetic products from flowing to customers. In terms of magnetization packaging, our company has track automatic coding magnetization equipment to prevent personnel from mischarging the magnetic charge.

In terms of delivery control, a large number of multi-line cutting machines, slicing units, mature technical processing workers, perfect product process monitoring, each step of product processing and production can get progress feedback at any time, mature cylindrical product production line, to ensure customer control requirements for product delivery, as well as controllable production progress.

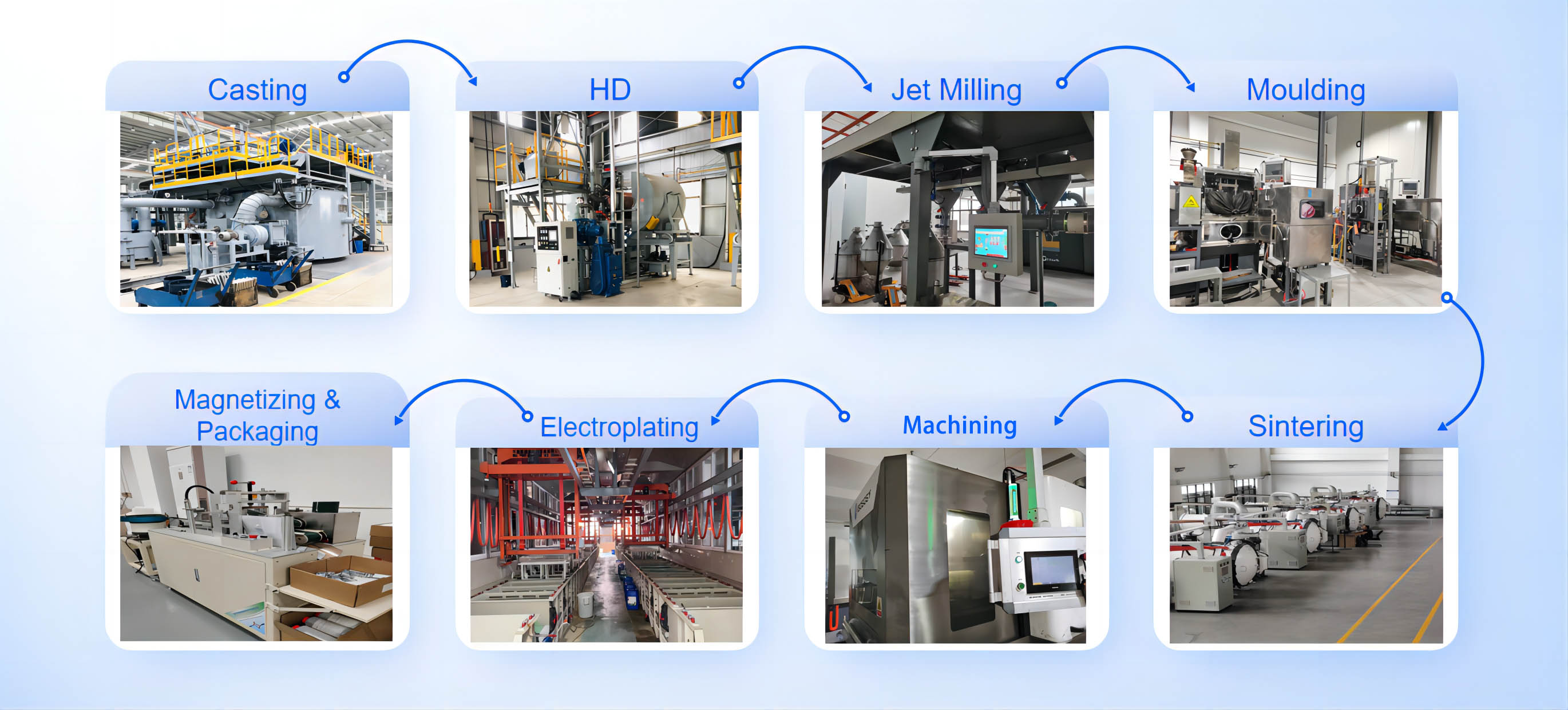

NdFeB Production Process

Coating Introduction

| Surface | Coating | Thickness μm | Color | SST Hours | PCT Hours | |

| Nickel | Ni | 10~20 | Bright Silver | >24~72 | >24~72 | |

| Ni+Cu+Ni | ||||||

| Black Nickel | Ni+Cu+Ni | 10~20 | Bright Black | >48~96 | >48 | |

| Cr3+Zinc | Zn C-Zn |

5~8 | Brighe Blue Shining Color |

>16~48 >36~72 |

--- | |

| Sn | Ni+Cu+Ni+Sn | 10~25 | Silver | >36~72 | >48 | |

| Au | Ni+Cu+Ni+Au | 10~15 | Gold | >12 | >48 | |

| Ag | Ni+Cu+Ni+Ag | 10~ 15 | Silver | >12 | >48 | |

| Epoxy |

Epoxy | 10~20 | Black/Grey | >48 | --- | |

| Ni+Cu+Epoxy | 15~30 | >72~108 | --- | |||

| Zn+Epoxy | 15~25 | >72~108 | --- | |||

| Passivation | --- | 1~3 | Dark Grey | Temporary Protection | --- | |

| Phosphate | --- | 1~3 | Dark Grey | Temporary Protection) | --- | |

Physical Characteristics

| Item | Parameters | Reference Value | Unit |

| Auxiliary Magnetic Properties |

Reversible Temperature Coefficient Of Br | -0.08--0.12 | %/℃ |

| Reversible Temperature Coefficient Of Hcj | -0.42~-0.70 | %/℃ | |

| Specific Heat | 0.502 | KJ·(Kg ·℃)-1 | |

| Curie Temperature | 310~380 | ℃ | |

| Mechanical Physical Properties |

Density | 7.5~7.80 | g/cm3 |

| Vickers Hardness | 650 | Hv | |

| Electrical Resistance | 1.4x10-6 | μQ ·m | |

| Compressive Strength | 1050 | MPa | |

| Tensile Strength | 80 | Mpa | |

| Bending Strength | 290 | Mpa | |

| Thermal Conductivity | 6~8.95 | W/m ·K | |

| Young's Modulus | 160 | GPa | |

| Thermal Expansion(C⊥) | -1.5 | 10-6/℃-1 | |

| Thermal Expansion(CII) | 6.5 | 10-6/℃-1 |

Picture Display