neodymium magnet, also known as NdFeB magnets, are a type of rare earth magnet and are widely used in various industries due to their strong magnetic properties. Known for their high resistance to demagnetization, these magnets are commonly used in applications such as electric motors, generators, and magnetic resonance imaging (MRI) machines. However, when it comes to neodymium magnets, a common question that comes up is: “What is the lifespan of a neodymium magnet?”

The service life of neodymium magnets can vary depending on a variety of factors, including the quality of the magnet, operating conditions, and its level of care and maintenance. Generally speaking, well-made neodymium magnets can have a service life of 20 years or more if used within specified operating parameters. However, it is important to note that improper handling, exposure to high temperatures and corrosive environments can significantly shorten the service life of these magnets.

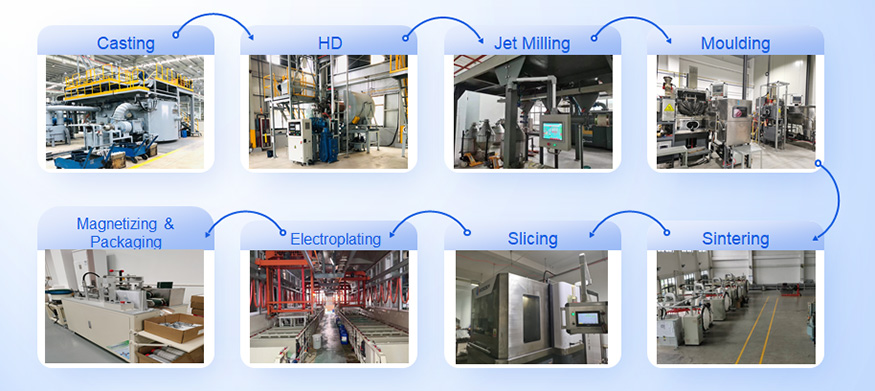

When manufacturing neodymium magnets, it is crucial to ensure that high-quality materials and precise manufacturing processes are used to produce the magnets. This is because any defects or impurities in the magnet can lead to shortened life and reduced performance. Therefore, it is essential to source neodymium magnets from reputable manufacturers who adhere to strict quality control standards.

In addition to the manufacturing process, customizing a neodymium magnet to meet specific requirements also affects its longevity. Custom magnets are often customized to operate in unique conditions, and if the customization is not done correctly, it can cause premature degradation of the magnet. Therefore, it is important to work with experienced professionals who understand the intricacies of custom neodymium magnets to ensure their longevity.

Additionally, the operating conditions under which neodymium magnets are used play an important role in determining their service life. These magnets are temperature sensitive, and exposure to high temperatures can cause them to lose their magnetism over time. Neodymium magnets must be operated within specified temperature ranges to ensure optimal performance and longevity.

Additionally, proper care and maintenance are critical to extending the life of your neodymium magnets. This includes protecting the magnets from physical damage, avoiding contact with corrosive materials, and storing them in a stable and controlled environment when not in use. Regular inspections and testing can also help detect any problems early and prevent potential damage to the magnets.

In summary, the service life of neodymium magnets is affected by a variety of factors, including manufacturing quality, customization, operating conditions, and maintenance. The service life of your neodymium magnets can be maximized by ensuring they are manufactured to high standards, customized correctly, operate within specified parameters and maintained properly. Ultimately, with the right care and attention, neodymium magnets can provide reliable and long-lasting magnetic performance for a variety of applications.

Post time: Jul-05-2024